Microstructure & Metallography

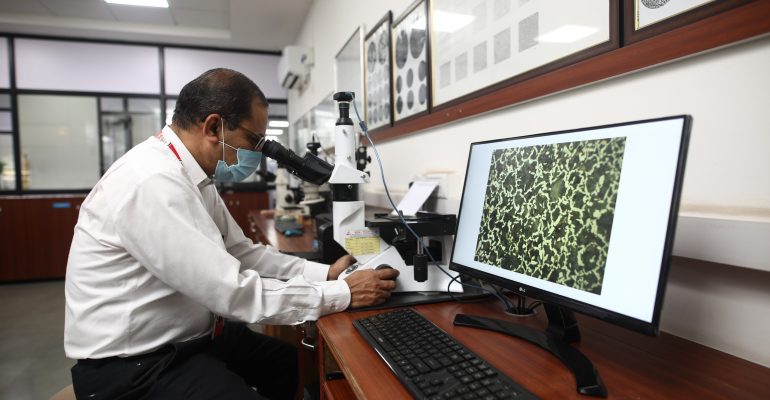

Embarking on a metallurgical journey, Metallographic analysis orchestrates the intricate dance of metal samples – a choreography involving cutting, mounting, and the artistry of grinding, polishing, and etching.

Embarking on a metallurgical journey, metallographic analysis orchestrates the systematic examination of metal samples, involving cutting, mounting, and precision techniques such as grinding, polishing, and etching.

These methodologies are pivotal in material characterization, quantifying various phases within alloy systems and correlating their presence with properties such as strength, corrosion resistance, and stability.

Microstructural analysis reveals the grain structure of materials, whether they are as-cast, wrought, heat-treated, or subjected to specialized treatments like carburizing or hardening. This analysis also identifies carbides, notably chromium carbide, which is critical in high-chromium, nickel alloys.

ELCA’s highly skilled metallurgists provide detailed insights into the metallurgical condition of diverse metals, including exotic alloys. Leveraging comprehensive application knowledge, our technicians deliver essential characteristics that aid customers in informed decision-making regarding material usage.

Various tests performed at ELCA encompass microstructure analysis at multiple magnifications with photographic documentation, grain size determination using carburizing and oxidation methods, phase analysis via image analysis, nodularity count utilizing image analysis, inclusion rating by ASTM E45, IS 4163, K4, K3 methods, coating thickness measurement through microscopic techniques, carbide morphology evaluation as per SEP 1520, and assessment of case depth and decarburization depth following IS 6416 and IS 6396 standards.

Furthermore, the determination of ferrite content according to ASTM E562 and ASTM A800/A800M standards is crucial for optimizing the properties of stainless steels and duplex steels, ensuring compliance with performance specifications.

Macroscopic examinations for grain flow in pipe, tube, and forged parts play a vital role in assessing structural integrity and mechanical performance. These examinations evaluate grain alignment, optimizing manufacturing processes and enhancing material properties for superior mechanical performance and durability.

Macroscopic inspections on mockups for minimum leak paths are essential in verifying the quality and reliability of welds and joints, crucial for applications requiring leak-tight seals. These examinations are pivotal in quality assurance, ensuring components meet rigorous standards for operational reliability and safety.

ELCA employs in situ metallography to conduct failure analysis directly in operational environments, providing timely insights into the root causes of material failures. This proactive approach supports industries in maintaining operational efficiency, safety, and asset reliability.

The integration of advanced image analysis systems into our high-power metallurgical microscopes enhances ELCA’s capability to deliver precise and informative images of metallurgical structures, supporting comprehensive material analysis and quality assurance initiatives.

Identification of Asbestos by Polarized Light Microscopy in bulk materials

Microstructure Analysis up to 1000 X Magnification

Macro on Forged Parts, Grain flow etc., with photo including M/c. Charges.

Austenitic Grain Size (Oxidation method-ASTM) Grain size by comparison method

.

Austenitic Grain Size (Carburizing method-ASTM).

Macro Test on Pipe & Tube, welded and seamless ,with Photos.

Case Depth by Microscopic Method (with Photo).

Inclusion rating by E45 method.

Computerized Image Analysis.

Inclusion Rating by K4 method.

Coating Thickness by Microscopic Method.

Decarb Depth by Microscopic Method

.

ISO 898(For Threaded samples).

Ferrite Content by Ferritoscope.

Surface roughness by RA meter.

Step Down Test.

Microstructure Analysis up to 1000 X with Photomicrographs.

In Situ Microstructure using Portable Microscopes

Macro and Weld Penetration using Stereo Microscopes (up to 50X)

.

Phase Analysis by Image Analysis Determination of Intermetallic Phases

.

Ferrite Content by E-562 method by Image analyzer.

Inclusion rating by IS 4163 method.

Nodularity Count by Image Analyzer

.

Inclusion Rating by K3 method.

Mc-qiid EHN Method (Grain Stability).

Carbide Morphology as per SEP 1520

.

Decarb Depth by Microscopic Method.

Coating Thickness by Fisher Dual scope.

Minimum Leak Path Tests.

Macro Examination for Mockups.